Batch control

Automation of

batch processes has become more transparent since commonly accepted standards

have been applied.

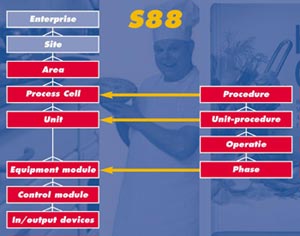

The S88-standard has been set up initially for control of batch processes. The most important characteristic of S88 is the separation between physical and the procedure model. The physical model describes all tools in the factory with their possibilities (methods). The procedure model describes how a certain product - using the available possibilities - must be made. The physical model can

be considered as a kitchen, completely with pans, mixers and a furnace. The procedure model

can be compared with a cooking book. The recipe for cake has been described in that book

as a procedure. The cake can in principle be made in every kitchen, but the working method will

always differ.

S88 lends itself for an object-oriented structure . Every physical component (control-module) or group describes components (equipment module) in the factory

which we use in our software object. Once developed and tested we can

re-use this software object for all identical physical components. Because of this we increase the reliability of application software considerably and

we save time and money (costs).

The S88-standard can be also applied in continuing and discrete processes. The physical model (the description of all tools in a process) can be incorporated without

restriction in

the S88-model. For the procedure model specific supplies in the field of stock processing and party management

are used. Micropulse Group uses among other things this model as a base for projects in the

food- and chemical industry.

|

Batch

control

Batch

control  Batch

control

Batch

control